Can Solar Improve Livelihoods for Small-Scale Farmers?

Across Sub-Saharan Africa, solar-powered appliances are becoming increasingly sophisticated and context-specific to meet the unique needs of off-and weak-grid communities. Solar companies continue to innovate new solutions to replace high energy-consumingor traditional fuel operated appliances – especially for agriculture. In Kenya, our team visited Agsol to learn how their solar-powered mills offer new income-generating opportunities for farming communities.

Solar Increasingly Powers Agriculture in Kenya

Over the past decade, the off-grid solar industry has grown to meet the energy demands of dispersed communities across Kenya, selling over 4 million solar lanterns and systems since 2016. As communities move up the energy ladder, solar-powered appliances improve the quality of life and offer new business opportunities.

In Kenya, agriculture plays a significant role in the economy, accounting for 40% of the overall workforce and contributing more than half of export earnings. The agriculture industry primarily consists of family-operated farms to meet both subsistence and commercial needs. Maize is a staple and can be eaten in popular maize dishes like Ugali, which is consumed by 78% of the population. However, there is a gap between raw maize production and the refining process to turn it into the commonly consumed flour. Because small-scale Kenyan farmers have limited access to milling machines, they rely on using third parties or mill manually. However, neither option is ideal. Milling through third parties is expensive, while manual milling does not produce a consistent grain texture. With access to smaller, more affordable mills, communities can improve agricultural productivity and the lives of off-grid communities.

Agsol Leads in Innovative Milling Technologies

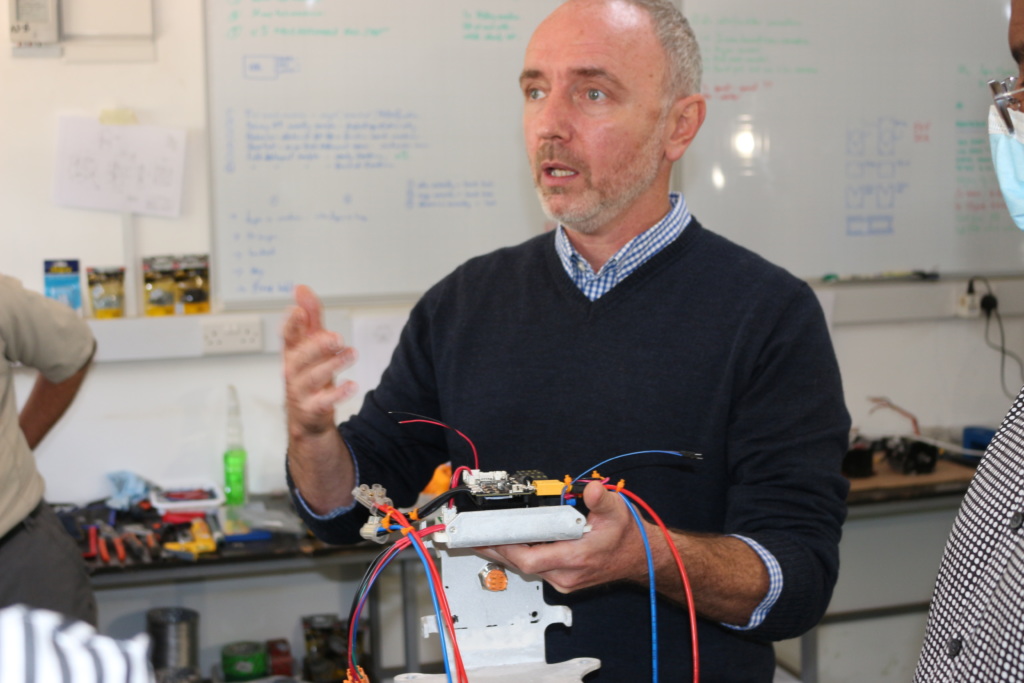

Agsol solar-mill

In 2016, Matt Carr and Greg Denn founded Agsol to build on early successes with “solarising” small agro-processing machines.

“Because diesel mills are large expensive machines and have really high operating costs, they are typically only found in larger towns and centres. That means most rural farmers waste huge amounts of time accessing these essential services. Our solar mills are specifically designed to be viable in smaller communities to bring milling services closer to the people that need them. They are cheaper to buy and cheaper to run than a diesel mill and can be operated by a non-trained technician.” explains Carr.

In 2019, Agsol won an Efficiency for Access R&D grant, which helped them develop the most efficient small grain mill known in the market. Our team has stayed in touch with Agsol since the grant. We recently visited their factory in Kikuyu to better understand their range of milling products and how farmers in Kenya use these appliances.

Agsol ’s Mills Offer Flexible Milling Hours

Agsol has developed a small hammer mill with interchangeable screens to produce fine flour or coarse grits for animal feed. Thanks to a specialized high-speed brushless DC (BLDC) motor, Agsol’s MicroMill is highly energy-efficient at converting power into flour – over 2.5 times more efficient than typical electric mills.

The Agsol MicroMill uses only 0.8kW, allowing for small quantity batch milling. This is not the case for diesel-powered mills, which can only mill in large quantities to conserve fuel. Diesel mill owners often make customers wait until there is sufficient volume to warrant starting up the diesel mill.

The need to conserve energy and mill in large quantities has led to millers setting specific milling times of the day, ensuring a large turnout of customers and large loads of cereal to be milled. In turn, solar mills offer flexible milling times as they consume less energy and can mill smaller batches.

“Customers told us the previous version of the MicroMill was too slow, and it needed to be twice as fast. That was our goal for the current version. But by developing our own custom BLDC motor, we’ve actually tripled the production speed, increased efficiency by another 30%, and reduced the costs by 45%. The MicroMill can process over 300 kg/day of flour, and we’re excited this product has real potential to outcompete diesel mills in most off-grid settings.” Carr explained.

Solar Mills Offer Opportunity to Power Other Appliances

Consumers have the option of purchasing the Agsol mills with a power offtake module that can supply 12V and 5V DC to power devices like phones, clippers, fans, TVs, etc. The mill comes with an LFP lithium-ion battery to store excess power during periods of high irradiation, providing energy during periods of reduced sun exposure.

Are Solar Mills the Future of Small-Scale Farming?

Electric-powered mills are the most cost-effective milling option for domestic and small-scale commercial use, especially in rural areas. With no running and negligible maintenance costs, mills pay for themselves in less than two years, while diesel mills use up to 35% of the generated revenue in maintenance and fuel costs. They are environmentally friendly and adequately sized to allow more distributed placement, reducing the time and labour burden associated with accessing milling services.

“Our mills have the potential to create a more decentralized and accessible network of essential services, saving rural women time otherwise spent walking long distances to and from diesel mills. They can be used as a source of [clean] energy as well as support new income-generating activities in small communities.”